Fighting Global Warming and Climate Change

NSK’s Approach

The NSK Group seeks to minimize CO2 emissions from its business operations to address the problems of global warming and climate change. Our specific efforts include making technical innovations in production processes, increasing production capacity, visualizing energy use, expanding the adoption of renewable energy, and strengthening energy-saving measures in logistics and offices. We aim to maximize the societal contribution of our products to CO2 emissions reductions in two categories: NSK product performance that directly contributes to the reduction of CO2 emissions (direct contributions), and NSK product applications that indirectly contribute to the reduction of CO2 emissions (indirect contributions).

Environmentally Friendly Products (related site)Information Disclosure Based on TCFD Recommendations (related site)

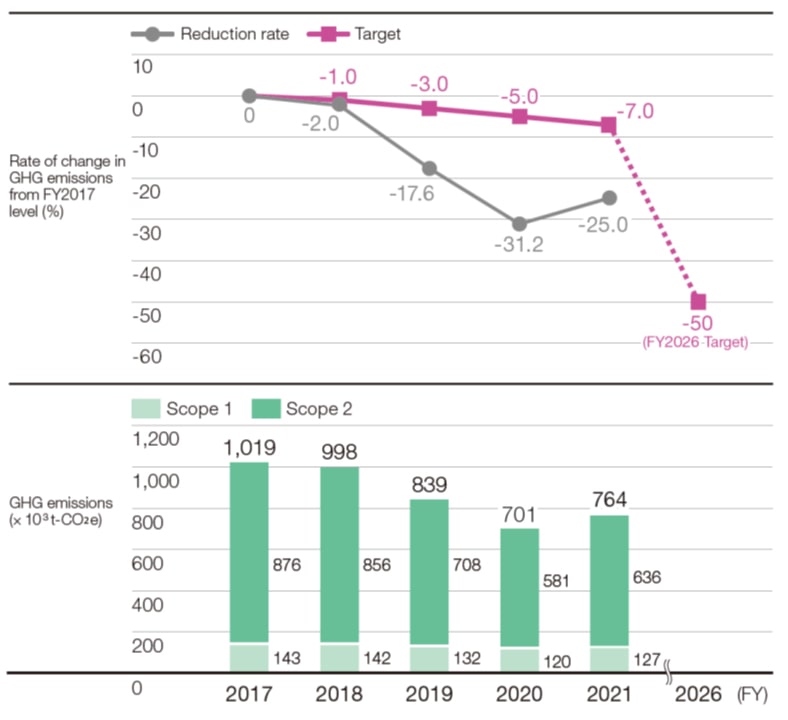

Targets and Performance

Sixth Mid-Term Management Plan Targets (FY2019–2021) and the FY2021 Targets and Performance

| Sixth Mid-Term Management Plan targets | FY2021 targets | FY2021 performance | Initiatives | |

|---|---|---|---|---|

| Manufacturing, technology, offices | CO2 emissions: *1 7% reduction from FY2017 |

948,000 t-CO2e*2 7% reduction from FY2017 |

764,000 t-CO2e*2 25.0% reduction from FY2017 |

(1) Production technology innovation

|

(2) Promotion of energy savings and fuel conversion

|

||||

(3) Expanded adoption of renewable energy

|

||||

(4) Mechanisms to promote measures

|

||||

| Distribution (Japan) | CO2 emissions by transport volume: 4% reduction from FY2017 |

4% reduction from FY2017 | Increased by 5.1% from FY2017 |

|

*1 Scope 1 and 2. The electricity emission factors for calculating Scope 2 emissions are the variable market standard. These emission factors, which change every year, are published by power companies with which we have contracts.

*2 CO2e refers to the CO2 equivalent: the emissions of a greenhouse gas multiplied by its respective global warming coefficient.

*3 Modal shift refers to the conversion of freight carried by trucks and other motor vehicles to railways and ships, which have a lower environmental impact.

Initiatives

Production Process Initiatives

Improving Productivity

The next-generation production line developed by the NSK Manufacturing Engineering Center, which is based on a new “Smart Factory” concept, increases productivity by reducing floorspace and shortening machining time. We have installed the new line at the NSK Ohtsu Plant and the Kirihara branch of the Fujisawa Plant, and we will roll it out to others, going forward. At the same time, we will work to reduce CO2 emissions by further promoting existing independent activities taken by plants to conserve energy.

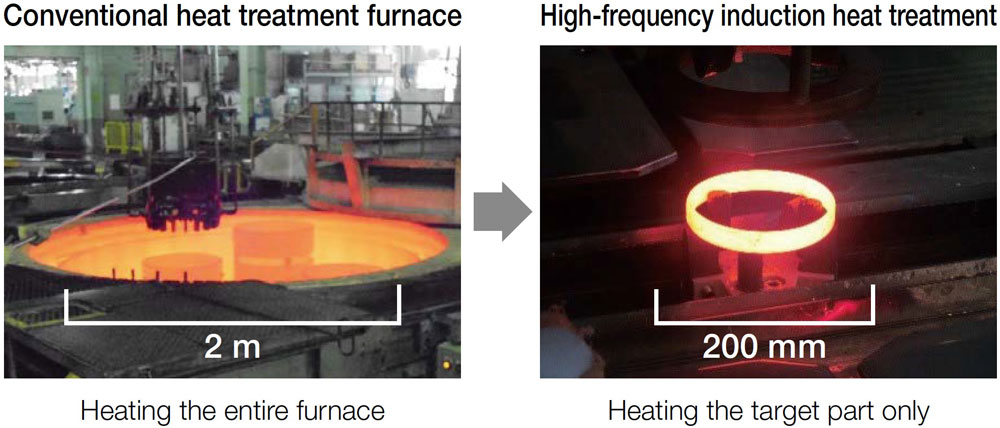

Adopting High-Frequency Induction Heat Treatment

Since high-frequency induction heat treatment only heats the target part, without heating the entire conventional furnace, we expect it to reduce energy consumption significantly and make a substantial contribution to reducing Scope 1 emissions. We have already introduced this method at the NSK Ishibe Plant, and we are gradually rolling it out to more products and other plants.

Visualizing Energy Usage

We are evaluating energy efficiency and discovering/reducing waste for each production line and piece of equipment by linking the electricity usage and operational status of each. This effort has already been deployed at Suzhou NSK Bearings Co., Ltd. in China, and is in development at the NSK Saitama Plant in Japan. In addition to electricity, we are also working to make air and fuel gas usage visible.

Coating Plant Roofs with Thermal Insulation Paint

Coating plant roofs with thermal insulation paint not only reduces radiant heat caused by sunlight in summer, but also prevents heat loss in winter. Since it has proved effective after application at NSK Saitama Plant, we are in the process of rolling it out to the Fukushima Plant and other plants. We also plan to apply this coating to the exterior walls of heat treatment furnaces to increase insulation and improve the work environment, while reducing the risk of fires.

Offices/Sales Initiatives

Adopting Green Electricity

In the European region, which is ahead in renewable electricity, we have switched to green electricity at both NSK Deutschland GmbH and the NSK European Distribution Centre (the Netherlands). We are moving to implement renewable energy not just at plants, but at offices as well.

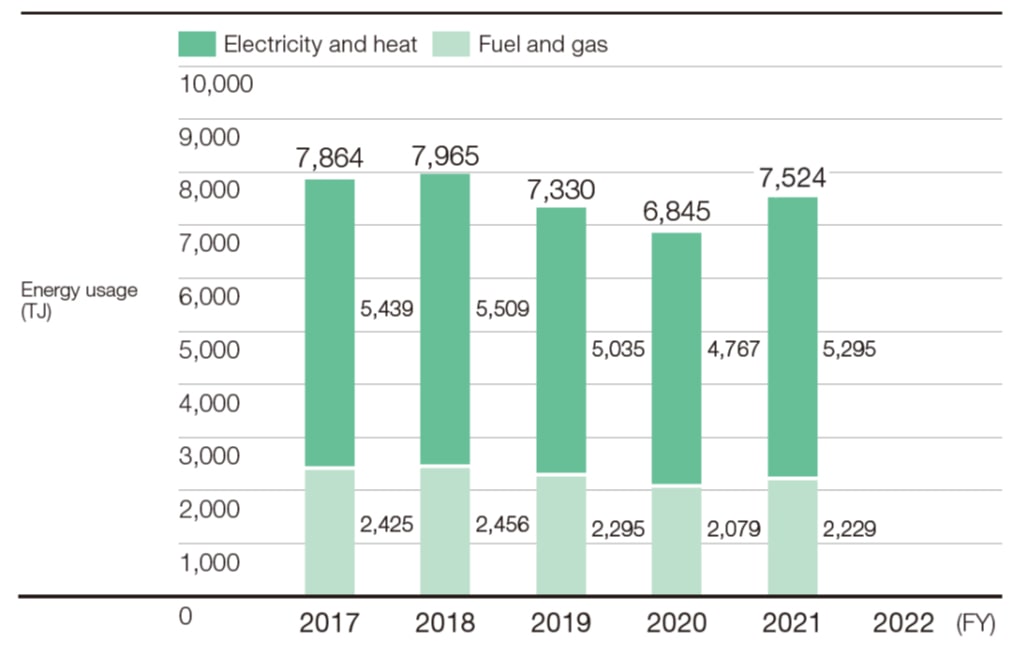

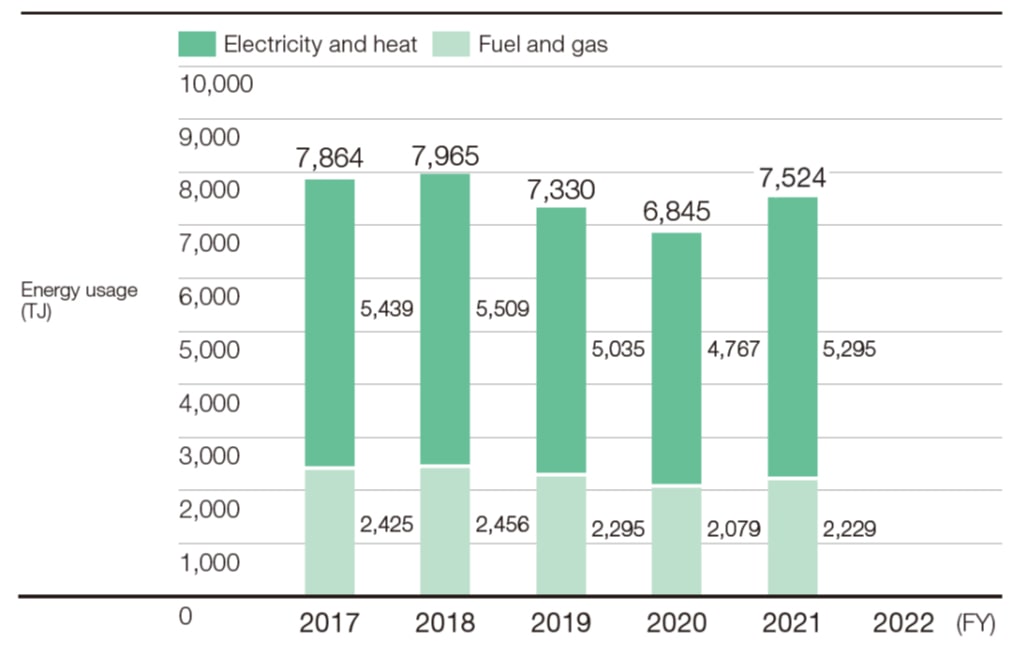

Energy Usage and CO2 Emissions

Energy Usage (Global)

Click to enlarge