Overview

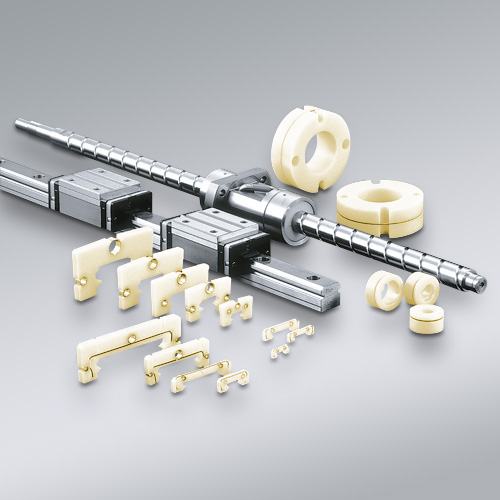

With the world's leading Ball Screw, NSK has been contributing to industrial growth. NSK Ball Screws were developed through cutting-edge tribology (friction control technology), and NSK manufactures the largest volume in the world with its outstanding production and quality control techniques. We offer a complete selection of Ball Screws, from miniature to ultra-large sizes, for machine tools, injection molding machines, and general machinery as well as for use under special environments, such as semiconductor and LCD production equipment.

CAD

Product List

High-Speed, Low-Noise Ball Screws BSS Series

High-Speed, Low-Noise Ball Screws BSS Series

Quiet and compact, with unparalleled high-speed performance. Low-noise BSS Series Ball Screws are suitable for an extensive range of uses, from transportation equipment to machine tools.

Features:

- Low noise

- High speed

- Compact design

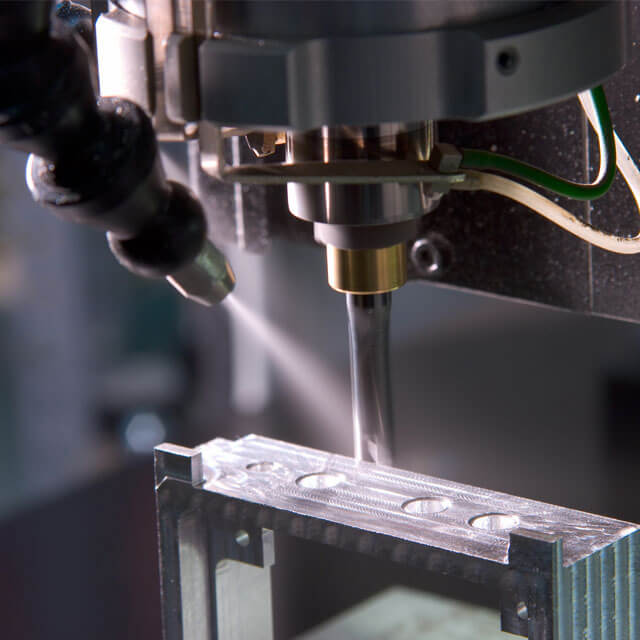

Ball Screws for High-Speed Machine Tools HMD Series / HMS Series

Ball Screws for High-Speed Machine Tools HMD Series / HMS Series

Upgraded version of the highly regarded HMC Series, featuring middle-deflector recirculation system that enables high-speed, low-noise operation. Nut cooling ball screw is also available.

Features:

- High-load capacity

- Low noise

- High speed

Ball Screws for Twin-Drive Systems TW Series

Ball Screws for Twin-Drive Systems TW Series

TW Series Ball Screws deliver the ideal functionality for twin-drive systems and easily realize the high rigidity, accuracy and responsiveness of twin-drive tables.

Features:

- High rigidity and long operating life

- High accuracy

- Excellent responsiveness

Ball Screws for Small Lathes BSL Series

Ball Screws for Small Lathes BSL Series

Unified component shape facilitates short-term delivery; end-deflector recirculation system adopted for high-speed and low-noise operation.

Features:

- Short-term delivery

- High speed and low noise

- Dust resistance

High-Speed, High-Load Ball Screws HTF-SRC Series/ HTF-SRD Series/ HTF-SRE Series/ HTF Series

High-Speed, High-Load Ball Screws HTF-SRC Series/ HTF-SRD Series/ HTF-SRE Series/ HTF Series

Easy-to-use ball screws for high-load applications. Wide variety of products suited for high-load drives.

Features:

- High-load capacity

- Low noise

- High-speed

Grease Retaining A1 Seal HTF-ASRC Type/ HTF-ASRD Type

Grease Retaining A1 Seal HTF-ASRC Type/ HTF-ASRD Type

The grease retaining characteristics of ball screws have greatly improved owing to the A1 seal. The A1 seal helps to maintain a clean and healthy environment.

Features:

- Grease retaining performance

- Clean environment maintenance

- Low friction torque and low heat generation

Lubrication Units NSK K1™

Lubrication Units NSK K1™

NSK K1 lubrication unit ensures long-term, maintenance-free operation and the long operating life of components under tough lubrication environments; clean lubrication method exerts less impact on the environment.

Features:

- Long-term, maintenance-free operation

- Long operating life

- NSK K1 for food processing or medical equipment also available

Highly Dust-Resistant Ball Screws V1 Series

Highly Dust-Resistant Ball Screws V1 Series

NSK's most advanced high-performance seals deliver more than four times longer service life under contaminated environments than conventional models.

Features:

- High dust-resistance (specially profiled ball groove of the screw shaft)

- Long operating life

NSK Ball Screws for Standard Stock Compact FA Series

NSK Ball Screws for Standard Stock Compact FA Series

Standard stock series for immediate delivery of BSS Series high-speed, low-noise Ball Screws; next-generation compact Ball Screws offer quiet, high-speed operating performance.

Features:

- Compact design

- Low noise

- High speed

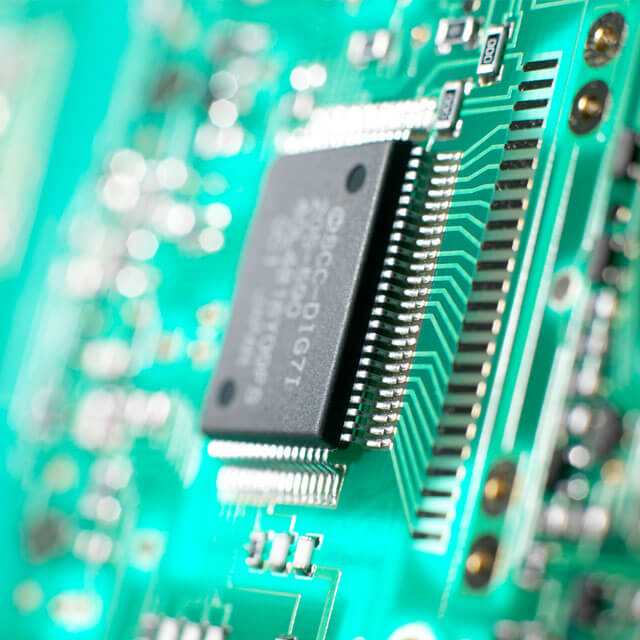

Ball Screws with E-DFO Thin-Film Lubrication for Vacuum Environments

Ball Screws with E-DFO Thin-Film Lubrication for Vacuum Environments

Further advanced DFO thin-film lubrication technology ensures significantly longer life and lower outgassinThin-Film Lubrication for Vacuum Environments Ball Screws with E-DFO for Vacuum Environmentsg in vacuum environments.

Features:

- Suitable for high vacuum environments

- Low outgassing

- Low friction